Russ King of Kwik Model 3D

Russ King has been in the HVAC Industry for more than 20 years and has became known as one of the leading pioneers of friction rate and airflow. I recently came across his blogs and have learned a lot from him. I was able to get an interview with him so lets get this rocking!

Estimated reading time: 12 minutes

Russ King – Kwik Model 3D

Tell us more about yourself

Until I went to college my friends and family all called me Rusty. Many still do, but I go by Russ now. It’s more mature. LOL. When I was a teenager, my dad told me that I was an “energy conservation expert”. I wasn’t sure exactly what he meant, but it really impressed me, so that’s what I ended up studying in college. I find out later that he was just calling me lazy.

Just kidding. I had a great family. My dad was an officer in the US Navy the whole time I was growing up. We lived all over the Pacific Ocean: Hawaii (twice), Japan, several places in CA. I graduated from high school on an island called Adak, in the Aleutians. There’s a new Netflix reality show about it, “Pirates Gold of Adak Island”. It’s hilarious to watch. Very overdramatized. They blow up an unexploded artillery shell at the bottom of a hill we used to sled on in the winter. They find gold coins on the beach where we had our senior ditch day.

While on Adak, I had an internship with the Aleutian Island National Wildlife Refuge. I fell in love with wildlife biology and went to Humboldt State University in northern California to study that. Chemistry kicked my butt, so I changed my major to Environmental Resources Engineering with an emphasis on Energy Resources. I was much better at math and physics and also learned a lot about buildings and how they use energy – building science basically.

I also learned about the importance of saving energy. Something that really sticks in my mind is that the percent of energy that is possible to be saved through more efficient technology and proper application of current technology and improved behavior is more than any single energy resource on the planet, coal, oil, gas, solar, wind, etc. I’ve dedicated my career to tapping into that resource. I especially think residential HVAC is one of the lowest hanging fruit there is.

What got you into this industry?

Where did you start?

My first job out of college was creating computer energy models of buildings at Davis Energy Group. My boss was a mechanical engineer named Marshall Hunt. He was the first ACCA certified instructor in CA. He taught me how to do Manual J, S, and D back in 1988, before there was any software. It was all done on worksheets. This was the early days of Manual J/S/D. Very few people knew about it.

How long were you in that position?

About four years. The company was bought out by another company and I stayed a couple more years, until I got my PE license.

What did you enjoy most about your work?

I enjoyed being one of the very few people who knew a lot about something (ACCA Manuals J/S/D). I was still in my twenties when I was teaching classes on HVAC design to people who had been in the industry for 30+ years. It was tough at times though. People really don’t like learning that they have been doing something wrong for 30+ years. Some old dudes got pretty rude about it. Luckily, I was able to show them the math and back it up with real world examples.

What kind of certifications do you have?

My main certification is my Mechanical Engineer’s license. I’m currently licensed in three states, CA, NV, and HI. I was licensed in CO for a while, but I let that lapse. I’m EPA 608 Universal certified. I’ve had a ton of certifications over the years, but if they are not required for the specific work I’m doing, I’ve let them expire. Those include various BPI certifications and HERS certifications. The knowledge is more important than the initials after my name.

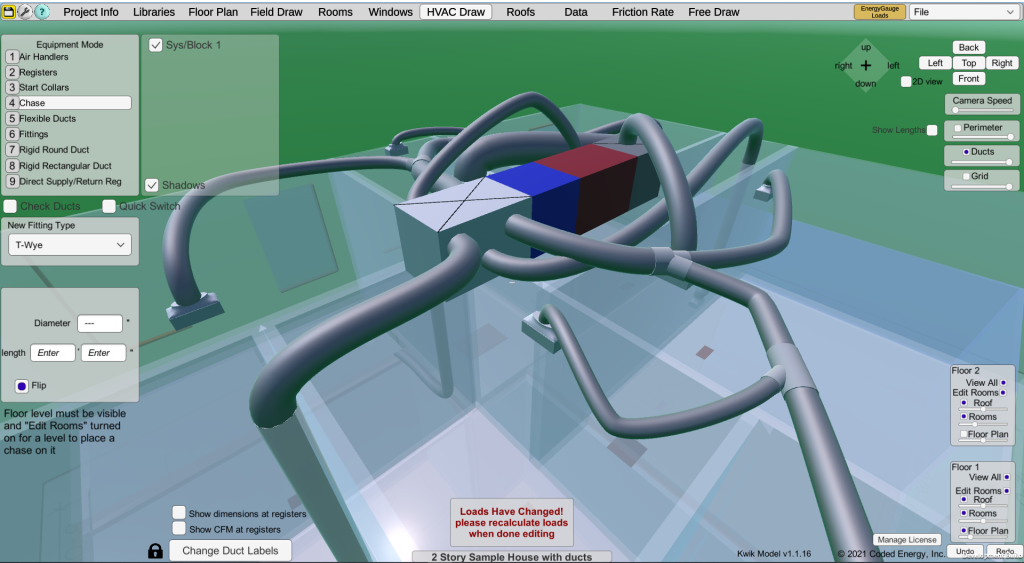

Kwik Model 3D

How did you start Kwik Model?

My son Connor graduated from UC Santa Cruz in 2018 with a degree in computer science. His dream job was to design video games. He had a real hard time finding a job. That’s a ridiculously competitive field. People will basically work for intern wages. He lived at home and I asked him to make a mock up for me of an idea that I wanted to show some people. His mock up turned out so good that I decided to run with it and I convinced him to start a company with me. We started Coded Energy, Inc. in October 2018.

What were some of the struggles that arises?

The first struggle was that we released our first version almost on the exact same day that the COVID pandemic started. That really took a lot of wind out of our sales, but overall, it has been a blessing. We survived and it allowed us to do a lot more testing on the software than we would have otherwise.

What pushed you into making Kwik Model 3D?

Having used and taught Wrightsoft and Elite for over 30 years. I wrote a blog article way back in 2013 (https://russellking.me/2013/05/25/why-we-need-a-simpler-hvac-design-methodology/) that complained partly about Manual J, but mostly about the available software. It made some people mad, but nothing changed. The software basically looks exactly like it did 30 years ago and is just as hard to use, if not more so. When the opportunity came to write my own software, I jumped on it. Kwik Model is the software I wish I had back when I was doing designs every single day and running very busy engineering departments.

What are the capabilities of Kwik Model?

The main thing is that it is 3D and it is fast. When people think of 3D, they think of Sketchup or Autocad and having to draw a house in 3D. Kwik Model builds a house out of 3D blocks. When you place a single block, you’ve just “drawn” four walls, a ceiling and a floor with one mouse click. It’s more like the Minecraft video game than a CAD program. The 3D visualization gives you a level of confidence in your design that you don’t get in other programs. I think this is very important.

Thanks to our partnership with EnergyGauge (by the Florida Solar Energy Center) our design package, Kwik Model with EnergyGauge Loads, is fully Manual J certified and we are very close to having our Manual D certification. As a licensed mechanical engineer, I can attest to the fact that Kwik Model currently does duct design in compliance with Manual D, we just don’t have the magic certification yet. EnergyGauge does. We are in the process of getting KM and EG to talk to each other so that the design you do in Kwik Model is sent to EnergyGauge, where it gets finalized and “blessed”.

What are your thoughts about software’s having internal database for equipment’s?

It’s very expensive and we have not had a lot of requests for it. In all my years of using Wrightsoft, I never trusted that feature. Sometimes we would go back and put in the same information and get different answers. We ended up not using it. I much preferred getting the data directly from the OEM spec sheets myself. It’s much more useful and informative, to me, to see the data in tabular form right in front of me. That’s how I teach Manual S too.

This sounds really paranoid, but I had a boss who once told me, “Always do a design with the assumption that someday someone is going to sue you over it.” That really stuck with me. I always keep very good records of where I got my information and why I made certain assumptions. I would photocopy the expanded data tables, highlight the numbers I used and stick it in a project folder for that job. Using an automated database did not allow that. If you got bad numbers from the database and got sued, they would ask if you verified those numbers against OEM data. If you have to verify the numbers, why even use the database? I also think that using a database makes people less likely to understand the interactions of outdoor DB, indoor DB, indoor WB, and airflow than if you see it in a table. It’s important for designers to know exactly where those numbers come from. That’s one thing I’m pretty old school on.

Modern Design Software

I noticed your software Kwik Model 3D is a whole lot simpler to use compared to other software such as Writghtsoft, Elite, Adtek, and the others. What makes your software unique to theirs?

I ran two mechanical engineering departments (ConSol and BORM Engineers) where we specialized in residential HVAC design. We used Wrightsoft. I was the Engineer of record on probably 2000-3000 designs. I was never happy with Wrightsoft, but back then there was no other option. We tried Elite when it came out, but it was basically a Wrightsoft clone.

What are some of the problems you had with them?

My blog article linked above talks a lot about that. They did enough to help us get by, but there were so many bugs and workarounds that it was kind of ridiculous. The worst part was trying to teach people how to use them. I taught a 3 day class for PG&E for several years. It was embarrassing. I was basically teaching them how to hack the software to make it work right. There was a lot of “don’t use this page”, “ignore all of this”, “this will screw up your numbers if this little button is checked”, “this doesn’t do what you think it does”, “just put any number here so you can continue”, “this has no impact on anything’, etc.

What did you like about them?

Having done Manual J S and D calculations by hand for a few years made software seem like a blessing from God. Even though they had their issues, we were able to make them work, but there were days when I wondered if it really was easier or not.

New software is always going to be tricky to learn. Is there any documentation, tutorials, or trainings you offer for Kwik Model 3D?

Yes. We have a pretty extensive YouTube channel. Just search for Kwik Model. In the Playlists, there are a couple of recorded classes that are quite in-depth. A few times a year, SoCal Edison hosts a training and I was just signed on to teach classes for PG&E. When those get scheduled, I usually post them on my blog and send out an email to all of our users. You can also get on the Edison and PG&E training mail lists. I’m also available for one on one training and design assistance to our users at greatly reduced hourly rates.

Trades not being properly informed

One of the things that bothers me in the trade are companies just sizing ductwork based on square footage of the home and not accounting for other factors. What are you opinions on this topic?

Oh, man. I could go on all day about this… The single biggest problem in the HVAC industry as it relates to sizing is the misconception that bigger is safer. I will tell you 100% that an oversized system will have more comfort issues than an undersized system. I challenge anyone to prove me wrong. Check out the video on my YouTube channel called “Fun with Dataloggers”. It’s a real eye opener.

Contractors get lazy and they say, “let’s go XXX square feet per ton”, then they round up a size thinking that they are playing it “safe”. That is a recipe for disaster. Then on the next house they say, “Well that last house did not work out so well, let’s go up a half ton on the next one.” Then they undersize the ducts! I would confidently say that the average house in CA, probably the entire US, has oversized equipment and undersized ducts. One of my main reasons for putting Kwik Model out there is that if we can make it faster and easier to do proper design, more contractors will do it and they will learn.

Do you think the industry is keeping people aware of this as of lately?

I think so. There seems to be a lot more training than there used to be. There are a lot of social media groups that seem to be focusing on the right stuff. I’m starting to more and more young HVAC contractors saying the exact right things and it brings a happy tear to my eyes. I’m only on Facebook, but there are some amazing people on the following groups that are really doing the right thing: HVAC Grapevine, HVAC School Group, the “Housh” as a System, Comfort Dynamics, TEC HVAC Airflow, Fans of Retotec\, etc. There are dozens.

I’ve learned that a good HVAC contractor owns a duct tester and a flow hood, but a great contractor also owns a blower door. What’s the difference? The first two test the HVAC system. The blower door tests the house. This means they understand the house’s role in comfort. I tend to beat up contractors pretty good. I would say that the “average” HVAC contractor is still way behind and very much still hurting the industry, but there are a bunch of really good ones out there. It’s tough. It’s `easier to make money doing it the easy/cheap/fast way. We all suffer for it in the end, though.

What kind of an impact would a homeowner have if their homes are incorrectly designed?

Well, less comfort, higher energy bills and shortened equipment life, to start. The problem is that homeowners have the same misconception that uninformed contractors do: bigger is better. Also, homeowners are only concerned with first-cost 95% of the time. They don’t want to pay for good design or quality installation. We need to educate homeowners as much as we need to train contractors.

Thank you for your time Russ King! Be sure to check out our Blog!